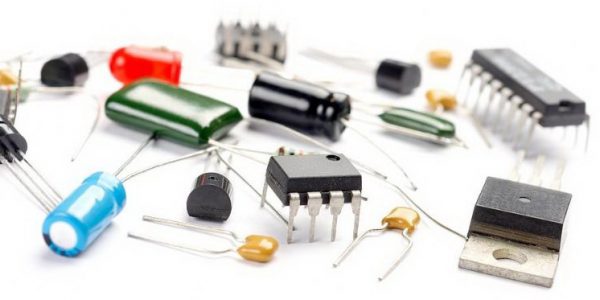

Resistors are ubiquitous. Due to of this the performance is always taken for granted, given they are worked within the voltage, power, as well as environmental ratings it is reasonable, as after several accumulated experience there’s a little left for the manufacturers to discover. However, there are applications where applying and specifying resistors has to get handled with a little care.

Resistor types – Mount chip

Resistor types – Mount chip

Most common purpose resistor is a thick film surface chip type. It is available in the huge quantities as well as low rates; it is a workhorse of resistor world. Construction is quite simple and does not vary from one manufacturer to another. The alumina substrate with the nickel plated terminations generally has the resistive ink printed or deposited on the top surface. These terminations are then coated with the solder dip just to ensure the ease of wetting whenever part gets soldered in place, and top of this part gets coated with the glass or epoxy layer to protect this resistive element.

The passive components Singapore manufacturers make different claims for ruggedness & performance of the parts but basic features are quite similar. The power dissipation is highly controlled by thermal properties of PCB pads in which this chip gets soldered, and suppose you’re running very close to a rated power of part it is essential to confirm your pad design will agree with manufacturer’s recommendations. You can get the metal film resistors for the higher performance applications, however, these are expensive than common thick film.